Impact energy

When buying a hydraulic hammer, one of the common questions is: how much impact energy does the hammer have? This should be correct approach and there should be a simple answer to this question.

Unfortunately, the impact energy data is used by many hydraulic hammer manufacturers in their catalogs, presenting their hammers as powerful tools. During the time, a kind of myth was created about the large impact energies providing hammers an effect of over 100%. Sometimes it seems that for some hammers it is enough to start them with the initial energy, and once they start like that, they continue to produce useful work indefinitely.

Sounds good, but it doesn’t work that way in the real world.

In a hydraulic hammer system, energy (which is transmitted by hydraulic oil) is delivered from the excavator to the hammer and passes through a series of obstacles while overcoming various resistances in the system. The energy delivered to the tool and to the material being broken is by no means equal to the initial energy delivered by the excavator. The difference between the energy delivered by the excavator and the energy delivered at the top of the tool is the efficiency rate and is always LESS than 100%.

In general and very roughly, the efficiancy of hydraulic hammers can be empirically summarized through the following table:

Hammer working weight, kg | Efficiancy, h | ||

<200 kg | 0,40-0,55 | ||

200-400 kg | 0,50-0,65 | ||

400-1000 kg | 0,60-0,75 | ||

>1000 kg | 0,65-0,85 |

Most manufacturers who state the data on impact energy in their brochures, state the efficiency of 100% (and even more), which is impossible. The table above shows that the actual values are up to twice less than those declared in some brochures.

A higher degree of hammer efficiency is achieved with quality finishing materials and sophisticated technical solutions.

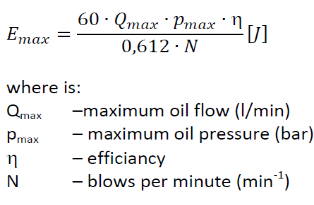

Furthermore, if we look at the expression for calculating impact energy:

It is interesting that when we include in the above formula the data from the brochures of some manufacturers, taking all the maximum values and 100% degree of efficiency, we still get lower values of impact energy than those declared in the brochures:-)

We also see that the impact energy depends on the number of strokes: the higher the number of strokes, the lower the impact energy. Of course, because here we are talking about impact energy, energy per stroke. The number of strokes per minute directly depends on the oil flow (and on the construction of the hammer / piston, control valve, ...) - the higher the oil flow, the higher the number of strokes and vice versa.

This basically means that the maximum oil flow will not necessarily give the maximum impact energy, ie any parameter at the maximum value does not mean the maximum hammer effect!

In practice, this means that increasing the amount of oil supplied to the hammer by increasing the engine speed of the excavator (by pressing the accelerator pedal) certainly means higher fuel consumption on the excavator, but it does NOT necessarily mean higher hammer efficiency!

Example from some brochure:

Hammer model | Hammer work. weight, kg | Oil flow, min (l/min) | Oil flow, max (l/min) | Work. press. min (bar) | Work press. max (bar) | Blows per min, (1/min) | Blows per min, max (1/min) | Impact energy, max (Joule) From brochure | Impact energy, max (Joule) Our calcul. |

A-lower middle class | 1760 | 140 | 175 | 160 | 180 | 400 | 800 | 4800 | 2100 |

B-top class | 1700 | 130 | 170 | 160 | 180 | 320 | 640 | N/A | 5700 |

In the example, we took for hammer A: degree of efficiency 0.55; for model B: 0.80.

Manufacturer B did NOT provide impact energy data in its brochure. Had he done so, he would probably have used the actual data and stated the impact energy towards AEM standard. However, then it would turn out that producer B has a weaker hammer than producer A, which is not true.

If we play a bit with prices, just to illustrate, we have the following situation:

Hammer model | Market value, EUR | Impact energy, Joule | Price per Joule |

A (from brochure) | 14.000,00 EUR | 4800 J | 2,9 EUR/Joule |

A ("real") | 14.000,00 EUR | 2100 J | 6,7 EUR/Joule |

B ("real") | 28.000,00 EUR | 5700 J | 4,9 EUR/Joule |

If a potential buyer were to compare manufacturer A (data from the brochure) and manufacturer B, it would seem that A is a bit weaker but twice as cheap! According to the ratio of price and delivered impact energy, A is the “best buy”. But when the data is inserted into the above formula, the situation changes and is closer to reality. Manufacturer B, although at first glance much more expensive, produces cheaper impact energy!

REMARK:

In this article, we wanted to point out the unrealistic data presented in various brochures and the, dare we say, unfair way of deceiving end customers with inaccurate data.

Hammers that are of a lower price range are more expensive to operate, this is clear in itself. There is no cheap and top notch at the same time. Of course, those users who have no interest in starting a business with a large initial investment and for whom higher production costs in operation do not represent a business obstacle, will certainly opt for, from our example, model A. And will have their own positive calculation. What we want to draw attention to is the transparent presentation of data.

Also, all of the above data are indicative. The most accurate data on the actual impact energies at the top of the peak are obtained by measuring under controlled conditions AEM-MBMB standard.

MBMB - Mounted Breaker Manufacture Bureau

AEM - The Association of Equipment Manufacturers