Warranty guidelines

In order to better understand the proper handling of the hammer in terms of extending the life of working tools and to avoid breakage, below are some useful tips from tool manufacturers on how to properly handle hydraulic hammers, what are the forms of tool breakages and warranty conditions for individual breakages.

|

|

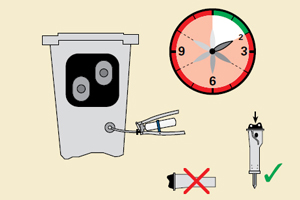

Lubricate the tool regularly. Excessive lubrication is manifested in the squeezing of grease down the tool, too little lubrication leaves the tool dry - optimal lubrication keeps the tool in the working part greasy but the grease does not drain down the tool. Self-lubricating hammers lubricate themselves while the operator can adjust the amount of lubricating grease consumption on the automatic lubricator. Hammers with manual lubrication require lubrication with a manual lubricator every 2-3 hours of hammer operation.

Hammer grease is produced with a special formula and ordinary lubricating grease must never be used. The purpose of the hammer lubricating grease is, in addition to the lubrication itself, partial sealing, which prevents the penetration of dust into the hammer and partial heat dissipation. Therefore, it is very important to use adequate grease to lubricate working tools. |

|

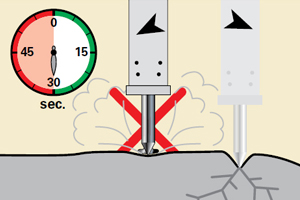

Move the hammer at regular intervals from one position to another to avoid overheating the tool. It is recommended NOT to work in one place without interruption for more than 30 seconds. Overheating of the tool leads to a change in the steel structure of the tool (tempering), which most often results in the creation of the so-called mushrooms on the top of the tool and in the worse case, when the tool cools down, the next hit immediately breaks the tool - we usually say that the tool cracked "like it was made of glass". |

|

|

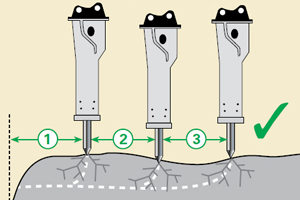

Moving the hammer in large steps will reduce your efficiency. Move the hammer in smaller steps - it saves the tool and increases work efficiency. |

|

|

|

|

|

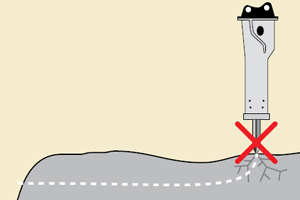

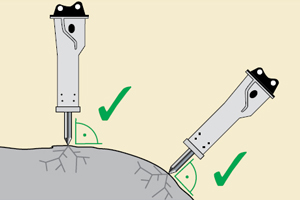

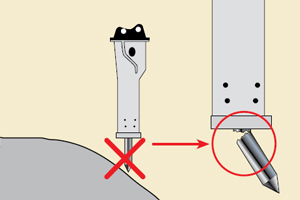

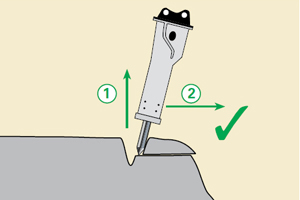

When working with a hammer, always place the hammer in such a way that the tool is in the vertical axis with the hammer. The tool should always be, as far as possible, in a vertical position in relation to the ground and the hammer. This ensures that the tool is guided correctly in the tool bushes and that tool breakage is avoided. |

|

|

|

|

|

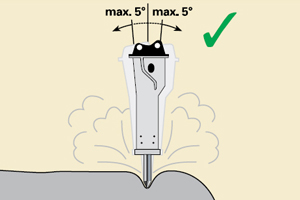

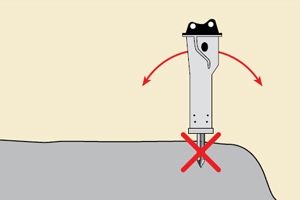

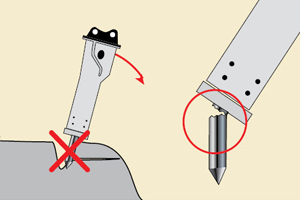

Slightly move the hammer back and forth when working. This is useful because you allow dust to be ejected under the tool blade. Never use a hammer as a lever! |

|

|

|

|

|

Try to avoid stressing the tool on bending - these are the most common fractures in practice. |

|

|

|

|