Fractures and Warranty conditions

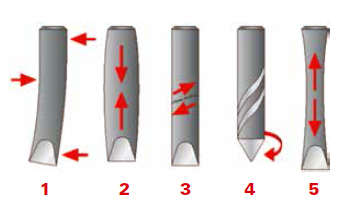

Working tools are subjected to various stresses that change during operation. These stresses can become extremely high if the hammer is handled improperly. A sudden increase in any of these stresses or a combination of multiple stresses can cause serious damage to tools and lead to tools fractures.

|

|

1. Bending stresses

2. Compressive stresses

3. Shear stresses

4. Torsion stresses

5. Tensile stresses |

Breaking typee |

Reason |

Result |

Warranty |

|

|

Heat treatment problem |

If the crack occurs 2-3 days after the installation of the new tool, the problem is in the heat treatment. If the crack occurs 2-3 months after the installation of a new tool, it is necessary to inspect the hammer. |

Accepted |

|

|

1 – Heat treatment problem

2 – Operator fault |

1 – If a crack occurs within max. a week after the installation of the new tool, it is a problem of heat treatment. 2 – If a crack occurs a week after the installation of a new tool and if deep scratches are visible on the tool in the bushing area , the crack occurs due to a of idle blows or due to improperly adjusted oil flow on the excavator. |

1 – Accepted

2 – Rejected |

|

|

Heat treatment problem |

It usually occurs 2-3 days after the installation of a new tool. |

Accepted |

|

|

Material fault |

It usually occurs 2-3 days after the installation of a new tool. |

Accepted |

|

|

Operator fault |

Visible damage to the working part of the bushings and tool retainers caused by excessive wear of the bushings. |

Rejected |

|

|

Operator fault |

Tool cracking caused by excessive bending. |

Rejected |

|

|

Operator fault |

The tool was used as a lever with excessive stress. |

Rejected |

|

|

Operator fault |

The tool was used as a lever with excessive stress. |

Rejected |

|

|

Wrong tool choice | Tool for softer materials used when working with hard materials |

Rejected |

|

|

Wrong working method |

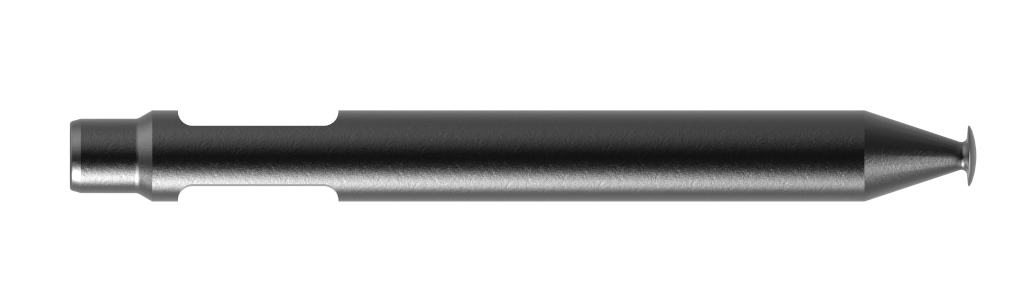

Blunting of the tip of the tool ("mushroom") occurs if you work in the same place for too long, which causes the tool tip to overheat and soften. |

Rejected |

Typical working tool failures

|

|

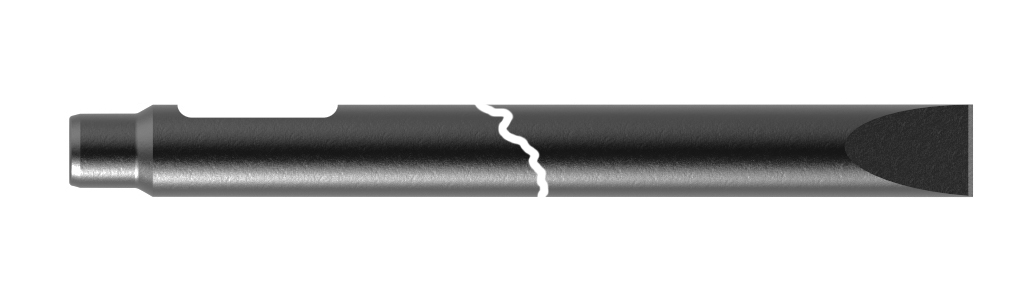

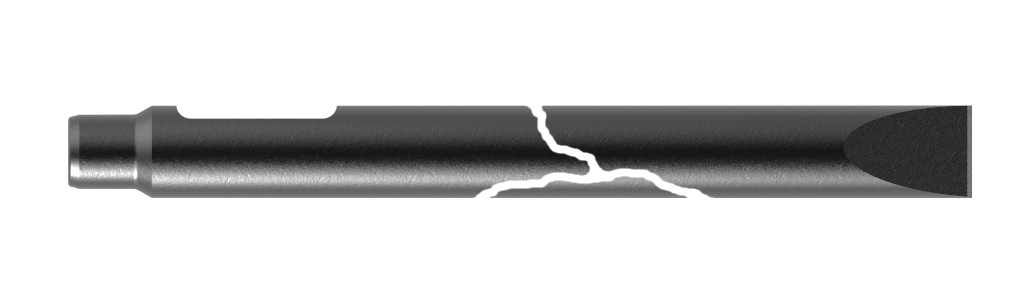

Bending fracture If the hammer is used as a ripper, when the tool penetrates the material at the same time the hammer pulls to either side, there are large lateral stresses that try to bend the tool while the hammer is in the wrong position - the tool is slanted, ie not aligned with the hammer axis - we say that the tool is used as a lever. A small initial crack usually appears which spreads in the direction of the lever by the cross-section of the tool and ends with a lip-shaped depression. |

|

Vibration failure These fractures occur by an undesirable combination of compressive stresses and shear stresses. These fractures usually occur with the appearance of an initial crack that spreads circularly transversely into the tool material and after the fracture is recognizable as a smooth surface. As these stresses spread, the tool becomes more and more sensitive to bending stresses, and at a critical moment for the material, a sudden fracture occurs. The rest of the cross-section is a fine-grained structure characteristic of fracture due to excessive bending. |

|

|

|

Torsional fracture It appears on the transverse chisels if the chisel "finds" a natural vein in the rock which it follows with a "line of least resistance" or twists in the direction of the vein. Large torsional stresses occur which can lead to such forms of rupture. |

|

Effect of idle blows on a working tools

|

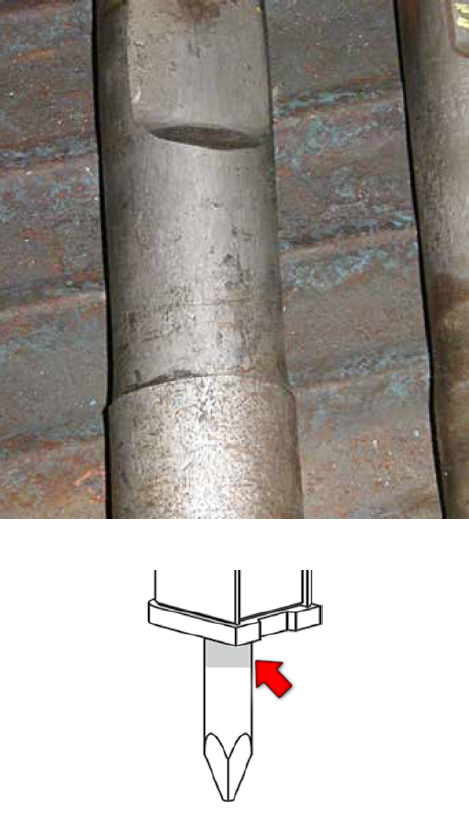

Wear and damage on the retainer bar recess edge (idle blows) Such damage occurs with too many idle blows. Idle blows are caused by the loss of a solid surface when the tool hits - most often by breaking thinner pieces of material, during which the tool, at a still high impact energy, continues the impact. This also happens by sliding the tool off a solid surface. In such cases, the impact energy is transmitted to the tool retainers instead of the material being broken. These stresses are also transmitted to the entire hammer but also to the excavator. Damage to the tool "neck" in the holder area can cause the tool pieces to tear, which can further reach the part between the tool and the piston and cause serious damage to the piston. |

|

Wear on the guide section (poor lubrication) Grooves that form on the tool in the part where it comes into contact with the bushes are almost impossible to avoid. Even with proper lubrication, direct contact between the tool and the bush (contact of two steels during movement) can occur, with very high temperatures of up to 1000 ° C developing locally. On such small surfaces, at the moment when the piston goes to the upper position and the tool stops, micro welding occurs. In the next stroke of the piston into the tool, these welded parts of the tool and the bush are torn, forming characteristic holes and grooves. Of course, in the absence of lubrication or when using inadequate tool grease, this phenomenon is frequent and intense. Therefore, proper lubrication is extremely important for preventing tools and bushings from excessive wear. Tip: Lift the hammer so that the tool hangs freely from the hammer. The tool will then lower and a thin film of grease should be visible on the part of the tool coming out of the hammer. If this film is not present, increase lubrication. If grease seeps down the tool the lubrication should be reduced. If the grease drains in a liquid state it is a sign that you are using the wrong grease. Always use grease to lubricate the working tools of hydraulic hammers! (English Chisel Paste, German Meißelpaste) |

|

|

Fractures resulting from material faults Typical fractures caused by a hidden defect in the material occur somewhere inside the material. The stress forces that propagate in the material encounter impurity or a small change in the structure of the material around which an increased stress concentration occurs. From this focus, the stress / force concentration spreads in concentric circles towards the outside of the tool. At a critical moment, the tool breaks. The cross-sectional area around the initial impurity is a smooth surface while the rest of the cross-sectional area at the time of fracture is a fine-grained structure. |

|

|